The structure and working principle of screw drilling tools

Screw drilling tool is a kind of positive displacement downhole power drilling tool that converts liquid pressure energy into mechanical energy by converting oil-based mud, floating mud and clay mud as dynamic fluid. When the high-pressure slurry generated by the slurry pump flows through the bypass valve into the motor, the rotor rotates around the axis of the stator under the drive of the pressure mud, and the torque and speed generated by the motor are transmitted to the drill bit through the cardan shaft and the transmission shaft, so as to realize the drilling operation.

The screw drilling tool is mainly composed of four parts:

1. Bypass valve assembly

2. Motor assembly

3. Universal shaft assembly

4. Drive shaft assembly

After more than 30 years of technical research, it has formed its own characteristic technology in terms of high torque, high power, high temperature resistance and long life, and has developed products suitable for special drilling conditions, such as rotary guide screw used in rotary guide speed acceleration application and high-build inclined screw applied to high-speed directional construction.

●Screw drilling tool model: 60, 73, 80, 89, 95, 102, 105, 120, 127, 135, 159, 165, 172, 175, 178, 185, 197, 203, 210, 216, 244, 286 and other more than 20 sizes.

●Motor specifications: 1/2, 3/4, 4/5, 5/6, 6/7, 7/8, 9/10 and other motor assemblies with a variety of heads and stages, which can provide a variety of speed and torque drilling tool combinations.

In view of the problem: in order to adapt to the drilling process due to the use of large displacement, large drilling pressure, high torque, high pumping pressure, high number of revolutions and other "three and two high" drilling parameters, large-displacement screw drilling tools products have been developed.

Technical solutions and features:

Large displacement: the new linear motor design is adopted to increase the overcurrent area of the drilling tool motor and reduce the sliding speed.

Erosion resistance: the transmission shaft adopts erosion resistant coating, and the bypass valve optimizes the design structure to meet the working conditions of large displacement and high sand content.

Model | flow rateL/s | rotate speedRPM | Motor pressure dropMPa | MAXOperating torqueN-m | Output powerkW |

172 Conventional screw | 19-28-38 | 86-126-173 | 4.0 | 13395 | 129 |

172Large displacement screw | 24-30-42 | 88-110-152 | 2.4 | 10022 | 86 |

127Conventional screw | 10-13-16 | 72-96-120 | 3.0 | 6429 | 75 |

127Large displacement screw | 10-16-22 | 60-100-139 | 2.4 | 6176 | 50 |

The third generation of ultra-high torque screw: In order to further meet the needs of unconventional oil and gas long horizontal section drilling speed, a super large torque screw with a strong combination of "pre-contour + hard rubber" is being developed, so that the output torque of the 172 screw drilling tool reaches more than 20,000 Nm, and the output torque of the 244 screw reaches more than 45,000 Nm.

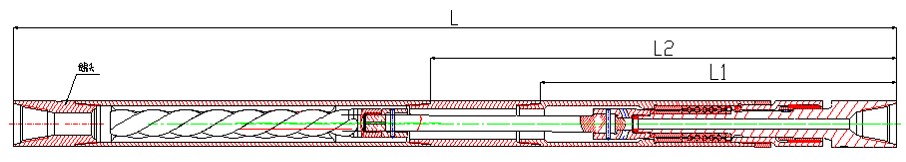

Double bending point high inclination screw: In order to meet the needs of high inclination use of small wellbore drilling on the window side, the lower part of the 73 screw adopts a double-curved shell (the maximum can reach 3 ° + 1 °), and the upper part adds a hinged joint (maximum angle 4 °), while shortening the distance between the bend point and the drill bit by 25%, and the theoretical slope reaches 48 °/30m, which meets the construction requirements of ultra-short radius horizontal wells.

class | firstBend point distanceL1(mm) | secondBend point distanceL2(mm) | total L(mm) | Upper connector |

Regular 73 screw | 845 | none

| 3860 | straight |

Double bend 73 screw | 652 | 998 | 2410 | Hinge connector (MAX angle 4°) |